Tired of glass railing installs that drag on because of misalignment, torque issues, or awkward base adjustments? When time is tight and complexity is high, delays, rework, and job site frustrations add up. This slows progress down and cuts into your schedule and bottom line.

You’re not alone in this. With decades of hands-on engineering and installation experience, ONLEVEL has seen the same challenges on countless job sites. That’s why we created TURBOFLEX, to eliminate unnecessary steps, reduce tolerance issues, and simplify alignment. All without compromising on strength or safety.

In this article, you’ll discover what sets TURBOFLEX apart, from its internal pivot mechanism to the way it helps contractors cut install time in half. Read how you can regain control of even the most complex setups.

What is Turboflex?

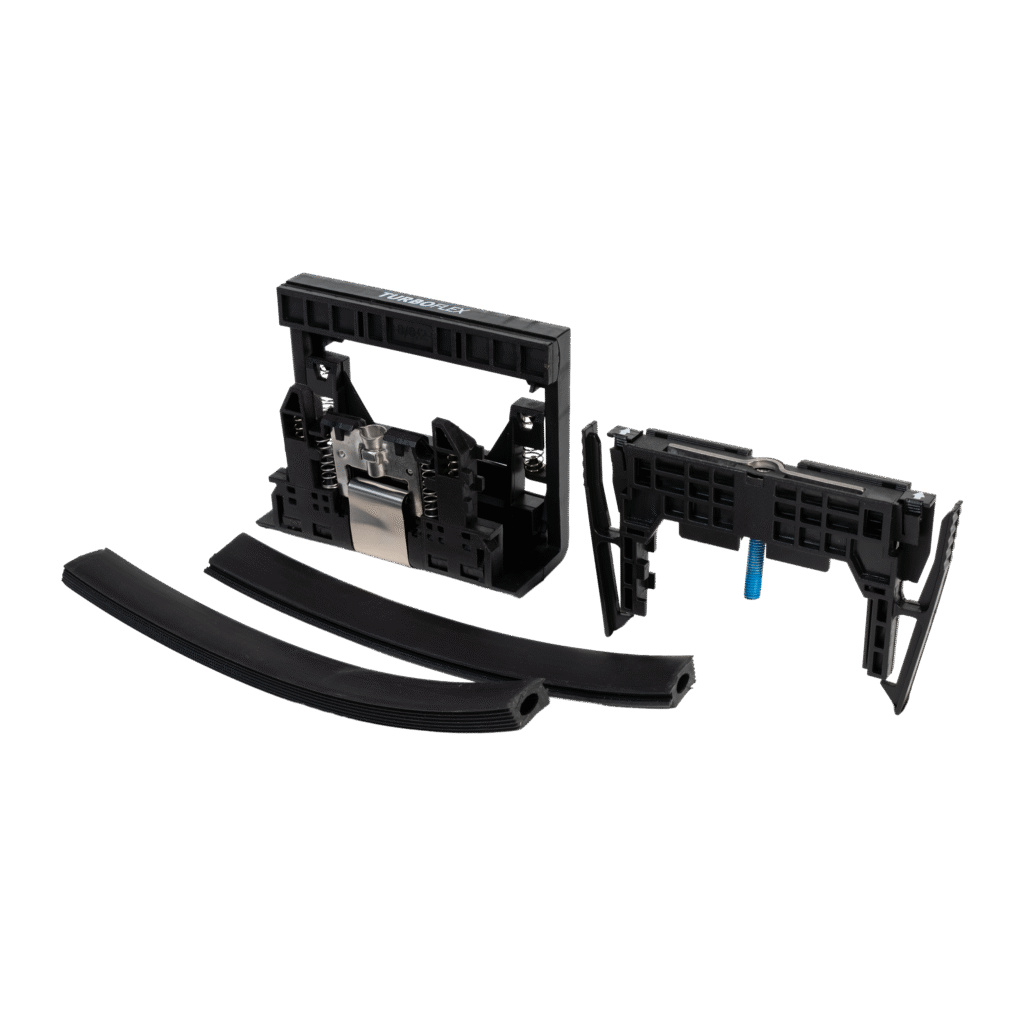

TURBOFLEX is an innovative glass railing system engineered to accelerate installation while ensuring uncompromised safety, precise alignment and refined aesthetics.

It flips the old approach on its head: instead of adjusting the glass fixation to suit the glass, TURBOFLEX adjusts to the glass itself, right where it matters, at the point of contact.

No rework. No trial-and-error. Just plug, place, align, and lock.

TURBOFLEX is designed to do one thing incredibly well: make glass panel installation faster, more accurate, and less stressful.

What Are the Key Benefits?

TURBOFLEX was engineered with a single goal: to make glass railing installation dramatically faster and easier, so that anyone can do it. Turboflex simplifies alignment, reduces manual adjustments and removes the need for special tools.

For Installation Companies

Metal and installation businesses operate at the intersection of precision, speed, and operational efficiency. Turboflex enhances all three:

- Millimetre-perfect alignment with ±2° horizontal and ±3 mm vertical adjustability

- Install safely from the user side

- Fast installation so you can go to next project

- Consistency across teams, even with junior or unexperienced mounters

- No extra tools needed

- Stress-free glass handling:

- Gaskets stay flush despite minor angle variation

- The pivoting mechanism eliminates point loading on the glass

- Works with 15–21.52 mm glass thickness

- What you place is what remains: no after-installation adjustments needed

- Reduced manpower due to simplified alignment

For Glass Processors & Dealers

Your customers need systems that are easy to specify, easy to trust, and operationally low-risk.

Turboflex delivers:

- A broad tolerance range, reducing complaints or returns

- A system that installers love, boosting repeat orders

- Simple, transparent value propositions for your sales team

- Reduced liability through certified performance (1.0 kN)

- Lower support overhead thanks to installation simplicity

For Hardware Dealers

Your business thrives on reliable, frictionless solutions that empower customers and differentiate your portfolio. Turboflex delivers:

- A product that “sells itself” because installation is universally simpler

- A demo box that enables hands-on showroom experiences

- Fewer technical queries: your customers succeed without complex guidance

- A differentiating product that positions your shop as future-ready

No matter who you are, whether expert or first-time installer, Turboflex gives you one less thing to worry about on-site. It’s designed to remove friction and boost your confidence at every step of the process.

What Makes It Different from Other Systems?

Let’s be honest: there’s no shortage of glass railing systems out there. Q-Disc, VetroMount, Defender 810, Balardo Core, offer competent solutions. Each has its loyal base of installers. So why does ONLEVEL claim Turboflex is something new?

Because it is.

Of course, we could simply say “TURBOFLEX is the best.” But you deserve better than that. So let’s break it down: clearly, transparently, and practically, from an installer’s point of view.

What problems does TURBOFLEX fix?

With traditional systems, adjusting the glass angle means adjusting the fixation itself, a process that’s far more complicated in practice than it sounds.

- Heavy, oversized panels: Large glass panels are difficult to handle with precision. The fixation is small and light, while the glass is heavy and awkward, making fine adjustments a challenge.

- Multiple fixation points: A typical 1-meter panel may have three fixations. In theory, all should be adjusted at once to change the angle. In reality, adjusting one leaves the others resisting movement, slowing the process.

- Material tolerances: Variations in delivered materials often prevent the system from functioning as intended.

On top of these issues, most systems share another critical flaw: adjusting the glass angle changes the way it contacts the fixation. A full contact area becomes just a narrow contact line. Over time, wind loads or line loads can cause the glass to shift, forcing costly re-adjustments.

With TURBOFLEX, the system adapts to your glass, right at the point of contact. You don’t align the glass to the profile. You align the glass exactly where it needs to sit. Then TURBOFLEX locks onto it.

That single reversal changes everything: less stress, less time, fewer tools, and fewer things that can go wrong. The Engineering

That Makes It Work

Here’s what makes TURBOFLEX fundamentally different:

Internal Pivot Under the Gasket

Traditional clamps fix rigidly to the profile, often creating tension when glass angles deviate even slightly. TURBOFLEX includes a built-in pivot directly under the sealing gasket, allowing the clamp to rotate and follow the angle of the glass.

Result? Always flush contact. No pressure points. No edge stress.

Fixing Is Done From One Side and Safely

Installing on a rooftop or balcony? Turboflex is fully accessible from the user-facing side. That means:

- No scaffolding

- No leaning over rail edges

- No costly safety setups

It’s safer and it’s smarter.

Faster by Design (Not Just by Claim)

TURBOFLEX installations are faster than conventional systems. Not because of magic, but because you eliminate:

- The need to pre-level the profile

- The back-and-forth to re-align glass

- Time spent compensating for glass tolerances

Place. Align. Lock. Done.

TURBOFLEX simplifies what used to be a complicated, time-consuming installation. With its internal pivot mechanism and one-side access installation, it gives you the speed, precision, and control you need, without sacrificing safety or aesthetics.

Installed in just three minutes, it eliminates rework, stress points, and tool-heavy workflows. TURBOFLEX changes how glass railing gets done. It adapts to your glass, your job site, and your schedule, whether you’re a solo installer or managing a full crew.

Want to see Turboflex in action? Request us a Demobox at sales@onlevel.com

TURBOFLEX simplifies what used to be a complicated, time-consuming installation. With its internal pivot mechanism and one-side access installation, it gives you the speed, precision, and control you need, without sacrificing safety or aesthetics.

Installed in just three minutes, it eliminates rework, stress points, and tool-heavy workflows. TURBOFLEX changes how glass railing gets done. It adapts to your glass, your job site, and your schedule, whether you’re a solo installer or managing a full crew.

With decades of practical experience and innovation in the field, ONLEVEL builds solutions for real-world challenges. TURBOFLEX is the result of that commitment, helping you install faster, safer, and smarter, every time.